2-Stroke Compression Ignition Cycle – Old-School Power Explained

Ever heard the roar of an engine that just sounds different? A raw, unadulterated power that seems to come from a simpler time? You might have just experienced the magic of a two-stroke compression ignition engine – a blast from the past that still holds its own in certain applications.

Understanding the inner workings of these engines can feel like deciphering an ancient code. The technical jargon can be dense, and finding clear, concise explanations can be surprisingly difficult. Many find themselves lost in the details, struggling to grasp the fundamental principles that make these engines tick.

This blog post aims to demystify the two-stroke compression ignition cycle. We'll break down the process into easy-to-understand steps, explore its advantages and disadvantages, and delve into the reasons why it remains relevant even in today's world of advanced engine technology.

We'll explore the core components, the unique two-stroke cycle, and the key differences between compression ignition and spark ignition. We'll also touch on the historical context, common applications, and the ongoing debates surrounding its efficiency and environmental impact. By the end, you'll have a solid understanding of this "old-school" powerhouse.

A Personal Encounter with Two-Stroke Power

My first real encounter with a two-stroke engine wasn't in a textbook or a technical manual; it was on a dusty trail, clinging to the back of a beat-up Yamaha DT175. My uncle, a man who knew more about engines than he did about poetry (and that's saying something), had resurrected the old bike from a junkyard. The thing smoked like a chimney and rattled like a box of bolts, but when he kicked it to life, it was like unleashing a tiny, angry dragon. The raw acceleration, the unmistakable "braap" of the exhaust – it was an experience I'll never forget. That's where my fascination with these engines began.

Looking back, I realize that ride was a perfect encapsulation of the two-stroke's appeal and its drawbacks. The power was immediate and exhilarating, but the fuel consumption was atrocious, and the noise pollution was… well, let's just say the neighbors weren't thrilled. The DT175, like many two-strokes, operated on a fundamentally different principle than the four-stroke engines found in most modern cars. Instead of four distinct strokes (intake, compression, power, exhaust), the two-stroke combines these processes into just two strokes of the piston. This simplicity, however, comes at a cost.

The simplicity translates to fewer moving parts, making the engine lighter and potentially more reliable. It also means that for every revolution of the crankshaft, there's a power stroke, theoretically doubling the power output compared to a four-stroke engine of the same size. This is why two-strokes are often favored in applications where power-to-weight ratio is paramount, like motorcycles and chainsaws. However, the two-stroke's design also presents challenges. The intake and exhaust ports are typically opened and closed by the piston itself, leading to less precise control over these processes. This results in some of the intake charge being lost out the exhaust port, reducing efficiency and increasing emissions.

Furthermore, two-stroke engines typically require oil to be mixed with the fuel to lubricate the internal components. This "pre-mix" system, while simple, contributes to higher emissions and can lead to "fouling" of the spark plug if the mixture is not precisely correct. Despite these drawbacks, the two-stroke compression ignition cycle continues to hold a special place in the hearts of engine enthusiasts. Its raw power, simplicity, and distinctive sound make it a legend in the world of internal combustion engines.

What is a Two-Stroke Compression Ignition Cycle?

The two-stroke compression ignition (CI) cycle, sometimes referred to as a two-stroke diesel cycle, is an internal combustion engine cycle that completes a power cycle with two strokes (up and down movements) of the piston during only one crankshaft revolution. This is in contrast to a four-stroke engine, which requires two revolutions (four strokes) to complete a power cycle. The defining characteristic of compression ignition is that the fuel is ignited by the heat generated from compressing air in the cylinder, rather than by a spark plug. This is the principle behind diesel engines.

Now, it's important to clarify that when we talk about "two-stroke compression ignition," we're typicallynotreferring to small, gasoline-fueled two-strokes like the ones found in chainsaws or weed eaters. Those engines typically use spark ignition. Two-stroke CI engines are more commonly found in larger applications, such as marine engines and some heavy-duty industrial equipment. These engines inject fuel directly into the cylinder near the top of the compression stroke. The high compression ratio (typically much higher than in spark-ignition engines) heats the air to a temperature that's sufficient to ignite the fuel upon injection.

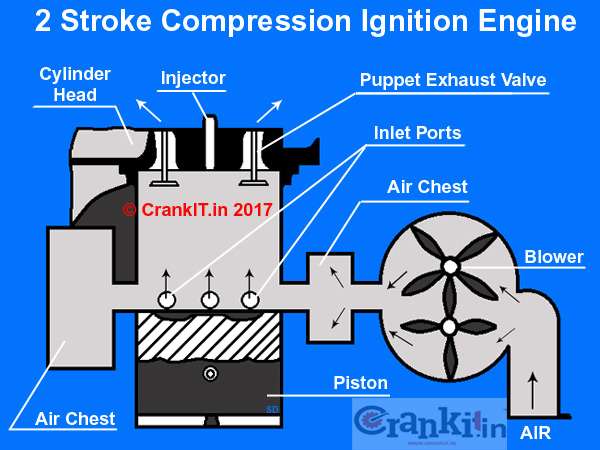

The sequence of events in a two-stroke CI engine is as follows: As the piston rises, it compresses the air in the cylinder. Near the top of the stroke, fuel is injected. The heat of compression ignites the fuel, creating a powerful expansion that forces the piston down. As the piston descends, it uncovers exhaust ports in the cylinder wall, allowing the burnt gases to escape. Simultaneously, or slightly before, the exhaust ports open, intake ports are uncovered, allowing fresh air to enter the cylinder, scavenging the remaining exhaust gases and preparing for the next cycle. The shape of the piston crown and the intake/exhaust ports are designed to optimize this scavenging process.

One of the key advantages of the two-stroke CI engine is its high power-to-weight ratio. Since it produces a power stroke with every revolution, it can generate significantly more power for its size and weight compared to a four-stroke engine. However, this also comes with challenges. Efficient scavenging is crucial for maximizing performance and minimizing emissions. Two-stroke CI engines are often more complex in their design than their spark-ignition counterparts, particularly in the fuel injection and scavenging systems. They also tend to be less fuel-efficient and produce higher emissions than modern four-stroke engines, which is why their use is becoming increasingly restricted in many applications.

History and Myths of the Two-Stroke Compression Ignition Cycle

The history of the two-stroke compression ignition engine is intertwined with the development of the diesel engine itself. Rudolf Diesel's original invention, patented in 1893, was a four-stroke engine that relied on compression ignition. However, engineers quickly explored the possibility of adapting the diesel principle to a two-stroke cycle. One of the early pioneers in this area was Joseph Day, who developed a simple two-stroke engine that used crankcase compression for scavenging. While Day's engine wasn't a compression ignition design (it used spark ignition), it laid the groundwork for future development of two-stroke engines.

Throughout the 20th century, two-stroke CI engines found widespread use in various applications. Large marine engines, used to power ships and submarines, were a particularly successful area. These engines could deliver immense power and were relatively simple to maintain. They also found applications in locomotives, generators, and heavy-duty industrial equipment. However, as environmental concerns grew, the two-stroke CI engine faced increasing scrutiny. Its inherent inefficiency and higher emissions compared to four-stroke engines led to stricter regulations and a gradual decline in its use.

One common myth about two-stroke engines is that they are inherently unreliable. While it's true that poorly maintained or improperly operated two-strokes can be prone to problems, well-designed and properly maintained two-stroke engines can be incredibly robust and long-lasting. Many large marine engines, for example, operate continuously for months or even years between overhauls. Another misconception is that all two-strokes are noisy and polluting. While older designs were certainly guilty of these characteristics, modern two-stroke engines, particularly those with advanced fuel injection and scavenging systems, can be significantly cleaner and quieter.

The history of the two-stroke CI engine is a story of innovation, adaptation, and ultimately, a struggle for survival in the face of increasing environmental pressures. While it may not be as ubiquitous as it once was, the two-stroke CI engine remains a testament to the ingenuity of early engine designers and its legacy continues to influence the development of modern engine technology.

Hidden Secrets of the Two-Stroke Compression Ignition Cycle

The true "secrets" of the two-stroke compression ignition cycle aren't about some arcane knowledge hidden away in dusty textbooks. Instead, they lie in the intricate engineering trade-offs required to make these engines work effectively. One of the biggest challenges is achieving efficient scavenging. In a four-stroke engine, the intake and exhaust strokes are dedicated to completely filling the cylinder with fresh air and completely removing the burnt gases. In a two-stroke, these processes must occur simultaneously during a much shorter period, while the piston is near the bottom of its stroke.

Engineers have employed various techniques to improve scavenging efficiency. One common approach is to use "loop scavenging," where the intake ports are angled to create a swirling motion that helps push the exhaust gases out of the cylinder. Another technique is "uniflow scavenging," where the intake ports are located at one end of the cylinder and the exhaust ports at the other, allowing for a more direct flow of air through the cylinder. Turbocharging and supercharging can also be used to increase the air pressure in the intake manifold, further enhancing scavenging.

Another crucial aspect is the design of the fuel injection system. In a two-stroke CI engine, the fuel injector must deliver a precise amount of fuel at the correct time to ensure efficient combustion. The fuel must also be atomized into very fine droplets to promote rapid and complete burning. Modern two-stroke CI engines often use electronic fuel injection systems with sophisticated control algorithms to optimize fuel delivery based on engine speed, load, and other operating conditions. The shape of the combustion chamber and the piston crown also play a critical role in promoting efficient combustion and minimizing emissions.

Finally, lubrication is a persistent challenge in two-stroke engines. Since there is no dedicated oil sump, the engine relies on oil mixed with the fuel or injected directly into the crankcase to lubricate the moving parts. This system, while simple, can lead to uneven lubrication and increased emissions. Engineers have developed various oil injection systems to improve lubrication efficiency and reduce oil consumption. The "secret" to a successful two-stroke CI engine lies in carefully balancing all these factors to achieve optimal performance, efficiency, and emissions.

Recommendations for Further Exploration of the Two-Stroke Compression Ignition Cycle

If you're truly fascinated by the two-stroke compression ignition cycle and want to delve deeper, I've got a few recommendations. First, seek out examples! Nothing beats seeing and hearing these engines in action. Visit a maritime museum, a vintage engine show, or even a construction site where heavy equipment is being used. Hearing the distinctive rumble and witnessing the raw power of a two-stroke CI engine firsthand will solidify your understanding and appreciation.

Second, explore online resources. There are countless websites, forums, and videos dedicated to engine technology. Look for technical papers, diagrams, and simulations that illustrate the inner workings of two-stroke CI engines. Pay particular attention to discussions about scavenging techniques, fuel injection systems, and emissions control strategies. Don't be afraid to ask questions and engage with other enthusiasts.

Third, consider taking a course or workshop on engine technology. Many vocational schools and community colleges offer programs that cover the fundamentals of internal combustion engines. These courses can provide you with a solid foundation in engine theory and hands-on experience with engine maintenance and repair. Finally, read books written by experts in the field. There are several excellent textbooks that cover the two-stroke compression ignition cycle in detail. Look for books that focus on engine design, combustion, and emissions control. By combining practical experience, online research, formal education, and in-depth reading, you'll gain a comprehensive understanding of this fascinating engine technology.

Delving Deeper into Scavenging Techniques

As we discussed earlier, scavenging is the heart of the two-stroke engine. Without efficient scavenging, performance suffers, and emissions skyrocket. Let's break down the main types: Loop scavenging, as the name suggests, directs the incoming air in a loop within the cylinder, sweeping out the exhaust gases. This is common in smaller two-strokes. Uniflow scavenging, typically found in larger engines, features intake ports at the bottom and exhaust valves at the top, creating a straight-through flow. This is generally more efficient but requires a more complex valve system. Cross scavenging, an older design, directs the incoming air across the cylinder towards the exhaust port. It's less efficient than loop or uniflow and is rarely used in modern engines. The design and placement of the ports are critical. They must be sized and angled to optimize airflow and minimize short-circuiting, where fresh air escapes directly out the exhaust port without scavenging the cylinder. Computational Fluid Dynamics (CFD) is now widely used to simulate airflow within the cylinder and optimize port design. Engineers can use CFD to visualize the flow patterns, identify areas of stagnation, and fine-tune the port geometry to achieve optimal scavenging efficiency.

Tips for Understanding the Two-Stroke Compression Ignition Cycle

Understanding the two-stroke compression ignition cycle can be challenging, but here are a few tips to make the process easier. Start with the basics. Make sure you have a solid understanding of the four-stroke cycle before diving into the two-stroke. The two-stroke cycle is essentially a simplified version of the four-stroke, so knowing the fundamentals of the four-stroke will give you a good foundation. Visualize the process. Use diagrams, animations, and even physical models to visualize the movement of the piston, the opening and closing of the ports, and the flow of air and fuel within the cylinder. Seeing the process in action will help you grasp the concepts more easily.

Focus on the key differences between two-stroke and four-stroke engines. Pay attention to the scavenging process, the lubrication system, and the fuel injection system. Understanding these differences will help you appreciate the unique challenges and advantages of the two-stroke cycle. Don't get bogged down in the details. While it's important to understand the technical aspects of the two-stroke cycle, don't get lost in the minutiae. Focus on the big picture and the fundamental principles. You can always delve into the details later. Seek out multiple sources of information. Don't rely on just one textbook or website. Read articles, watch videos, and talk to experts to get a well-rounded perspective.

Practice, practice, practice. The more you work with engines, the better you'll understand them. If possible, try to get some hands-on experience with two-stroke engines. Disassemble and reassemble an engine, or even just watch a mechanic work on one. Finally, remember that learning takes time. Don't get discouraged if you don't understand everything right away. Keep studying, keep practicing, and keep asking questions. With persistence and dedication, you'll eventually master the two-stroke compression ignition cycle.

Understanding Fuel Injection Systems in Two-Stroke CI Engines

The fuel injection system is arguably the most critical component of a modern two-stroke CI engine. It must deliver a precise amount of fuel at the correct time to ensure efficient combustion and minimize emissions. Early two-stroke CI engines used mechanical fuel injection systems, which were relatively simple but lacked the precision and control of modern electronic systems. These systems typically used a fuel pump driven by the engine to deliver fuel to the injector, which was mechanically actuated by the engine's camshaft. The timing and duration of the injection were determined by the cam profile. Modern two-stroke CI engines almost universally use electronic fuel injection (EFI) systems. These systems use sensors to monitor various engine parameters, such as engine speed, load, temperature, and exhaust gas composition. The sensor data is fed into an electronic control unit (ECU), which uses sophisticated algorithms to calculate the optimal fuel injection timing and duration. EFI systems offer several advantages over mechanical systems. They can precisely control the amount of fuel injected, allowing for optimal combustion efficiency and reduced emissions. They can also compensate for changes in altitude, temperature, and other operating conditions. Furthermore, EFI systems can be used to implement advanced features such as lean-burn operation and exhaust gas recirculation (EGR). The fuel injectors used in two-stroke CI engines are typically high-pressure injectors that can deliver fuel at pressures of up to 2,000 bar. These injectors are designed to atomize the fuel into very fine droplets, which promotes rapid and complete combustion. The design and placement of the injector are also critical for optimizing combustion efficiency. The injector must be positioned to ensure that the fuel is evenly distributed throughout the combustion chamber and that it mixes effectively with the air.

Fun Facts about the Two-Stroke Compression Ignition Cycle

Did you know that some of the largest internal combustion engines in the world are two-stroke CI engines? These behemoths, used to power massive container ships, can be as tall as a four-story building and weigh hundreds of tons! They can generate tens of thousands of horsepower and burn hundreds of gallons of fuel per hour. Another interesting fact is that two-stroke CI engines have been used in submarines for decades. Their high power-to-weight ratio and relatively simple design make them well-suited for underwater propulsion. However, their emissions have become a concern in recent years, and some navies are now switching to alternative propulsion systems.

Here's another tidbit: two-stroke CI engines can run on a variety of fuels, including diesel, heavy fuel oil, and even biofuels. This fuel flexibility makes them attractive for use in remote locations where access to conventional fuels is limited. One more fact: two-stroke CI engines were once used in locomotives. In the mid-20th century, several manufacturers produced diesel-electric locomotives powered by two-stroke CI engines. These locomotives were known for their high power output and relatively low weight, but they were also notoriously noisy and polluting.

Finally, a fun fact that might surprise you: some modern two-stroke CI engines are equipped with advanced technologies such as common-rail fuel injection, variable valve timing, and exhaust gas recirculation. These technologies help to improve fuel efficiency, reduce emissions, and enhance performance. So, despite their reputation as being old-fashioned and dirty, two-stroke CI engines are still evolving and adapting to meet the challenges of the 21st century. They might not be as ubiquitous as they once were, but they remain a fascinating and important part of engine history.

How to Maintain a Two-Stroke Compression Ignition Engine

Maintaining a two-stroke compression ignition engine requires a different approach than maintaining a four-stroke engine. Due to the unique design and operating characteristics of two-strokes, specific maintenance procedures are crucial for ensuring optimal performance and longevity. One of the most important aspects of two-stroke maintenance is proper lubrication. Since two-stroke engines typically rely on oil mixed with the fuel or injected directly into the crankcase, it's essential to use the correct type and amount of oil. Using the wrong oil or an incorrect oil-to-fuel ratio can lead to engine damage. Always follow the manufacturer's recommendations for oil type and mixing ratio. Regular inspection and cleaning of the fuel injection system are also critical. Dirty or clogged fuel injectors can lead to poor combustion, reduced power, and increased emissions. Clean the injectors periodically using a fuel injector cleaner or by removing them and cleaning them manually.

Another important maintenance task is cleaning or replacing the air filter regularly. A dirty air filter can restrict airflow to the engine, reducing power and increasing fuel consumption. Inspect the air filter frequently and clean or replace it as needed. Also, check and clean the spark plug regularly. A fouled spark plug can cause misfires and poor performance. Clean the spark plug with a wire brush or replace it if it's worn or damaged. Pay attention to the exhaust system. Two-stroke engines tend to produce more soot and carbon buildup than four-strokes, so it's important to clean the exhaust ports and exhaust system periodically. Carbon buildup can restrict exhaust flow and reduce engine performance. Finally, perform regular compression tests. A compression test can reveal problems with the piston rings, cylinders, or valves. If the compression is low, it may indicate the need for an engine overhaul. By following these maintenance tips, you can keep your two-stroke compression ignition engine running smoothly and efficiently for years to come.

What If the Two-Stroke Compression Ignition Cycle Disappeared?

Imagine a world without the two-stroke compression ignition cycle. What would be the consequences? In some areas, the impact would be minimal. For example, the vast majority of passenger vehicles already use four-stroke engines, so the disappearance of two-strokes wouldn't have a significant impact on the automotive industry. However, in other areas, the impact would be more profound. The marine industry, for example, relies heavily on large two-stroke CI engines to power cargo ships and tankers. Without these engines, the global shipping industry would face significant challenges. Alternative propulsion systems, such as four-stroke engines or electric motors, would need to be developed and implemented, which could be costly and time-consuming. The construction and mining industries would also be affected. Many heavy-duty construction and mining equipment, such as excavators, bulldozers, and loaders, are powered by two-stroke CI engines. The disappearance of these engines would require the development of alternative power sources for this equipment.

Certain niche applications, such as chainsaws and leaf blowers, would also be impacted. While four-stroke engines are becoming more common in these applications, two-strokes still offer a significant power-to-weight advantage. The disappearance of two-strokes would likely lead to the development of smaller, lighter four-stroke engines or the adoption of electric power. The biggest impact, however, would likely be on developing countries. Two-stroke engines are often used in motorcycles and other small vehicles in developing countries due to their simplicity, low cost, and ease of maintenance. The disappearance of two-strokes could make transportation more expensive and less accessible for many people in these countries. Overall, the disappearance of the two-stroke compression ignition cycle would have a mixed impact. While some industries would be largely unaffected, others would face significant challenges. The development of alternative power sources and the adoption of new technologies would be necessary to mitigate the impact.

Listicle of 5 Key Aspects of the Two-Stroke Compression Ignition Cycle

Here's a quick listicle summarizing the key aspects of the two-stroke compression ignition cycle:

- Two Strokes: The entire power cycle is completed in just two strokes of the piston, unlike four-stroke engines.

- Compression Ignition: Fuel is ignited by the heat generated from compressing air, eliminating the need for a spark plug.

- Scavenging: Efficient scavenging is crucial for removing exhaust gases and filling the cylinder with fresh air.

- Lubrication: Oil is typically mixed with the fuel or injected directly into the crankcase for lubrication.

- High Power-to-Weight Ratio: Two-stroke CI engines offer a high power output for their size and weight.

These five key aspects highlight the unique characteristics of the two-stroke compression ignition cycle. Understanding these aspects is essential for anyone who wants to learn more about this fascinating engine technology.

Question and Answer about the Two-Stroke Compression Ignition Cycle

Here are some common questions and answers about the two-stroke compression ignition cycle:

Question: What are the main advantages of a two-stroke CI engine?

Answer: The main advantages are its high power-to-weight ratio, simple design, and relatively low cost.

Question: What are the main disadvantages of a two-stroke CI engine?

Answer: The main disadvantages are its higher emissions, lower fuel efficiency, and challenging lubrication requirements.

Question: Where are two-stroke CI engines commonly used?

Answer: They are commonly used in large marine engines, heavy-duty industrial equipment, and some niche applications like chainsaws.

Question: How does a two-stroke CI engine differ from a four-stroke engine?

Answer: A two-stroke engine completes a power cycle in two strokes of the piston, while a four-stroke engine requires four strokes. Two-stroke engines also use scavenging to remove exhaust gases and have different lubrication systems.

Conclusion of Two-Stroke Compression Ignition Cycle – Old-School Power Explained

The two-stroke compression ignition cycle, a testament to engineering ingenuity, continues to fascinate and intrigue. While not as prevalent as in the past due to emissions concerns, its legacy persists in specific applications where its high power-to-weight ratio remains advantageous. Understanding its core principles, from the two-stroke combustion process to the crucial role of scavenging, provides valuable insight into the world of internal combustion engines. From the roar of a vintage motorcycle to the immense power of a marine engine, the two-stroke CI cycle has left an indelible mark on engineering history. Its story is one of innovation, adaptation, and the ongoing quest for efficient and powerful engines.

Post a Comment for "2-Stroke Compression Ignition Cycle – Old-School Power Explained"