Air-Fuel Ratio – Why Getting It Right Is Critical for Performance

Ever wondered why some engines roar with power while others sputter and struggle? Or perhaps you've noticed a dip in your fuel economy, leaving you scratching your head? The secret often lies in a seemingly simple ratio: the air-fuel ratio. It's the Goldilocks of engine performance – get it just right, and your engine purrs like a kitten, delivers optimal power, and sips fuel efficiently. But stray too far in either direction, and you're in for a world of trouble.

Imagine your engine isn't performing at its best. Maybe it's sluggish, unresponsive, or just plain unreliable. You're spending more on fuel, facing potential repair bills, and feeling frustrated with the overall driving experience. These issues, while seemingly disparate, can often be traced back to a single, crucial factor: the balance of air and fuel in your engine.

This article will explain why maintaining the correct air-fuel ratio is absolutely critical for achieving peak performance, optimal fuel efficiency, and long-term engine health. We'll delve into the science behind this ratio, explore the consequences of getting it wrong, and provide practical tips for ensuring your engine receives the precise mixture it needs to thrive.

We'll explore the intricacies of the air-fuel ratio (AFR), why it matters so much for performance, efficiency, and engine longevity. From understanding the ideal AFR to troubleshooting common issues and uncovering hidden secrets, this guide will equip you with the knowledge to ensure your engine is running at its best. We'll also tackle common myths, offer practical recommendations, and provide fun facts to enhance your understanding. Let's dive in and unlock the power of a perfectly balanced air-fuel ratio!

The Importance of Stoichiometry

My first real understanding of air-fuel ratios came during a particularly frustrating track day. I'd spent months tuning my engine, tweaking every parameter I could think of, but I was still down on power compared to my rivals. It was bewildering. I was convinced I had a hardware problem, but a seasoned mechanic suggested I take a closer look at my air-fuel ratio. He pointed out that I was running consistently rich, meaning I was dumping too much fuel into the cylinders.

Initially, I scoffed. "More fuel equals more power, right?" Wrong. He explained the concept of stoichiometry, the chemically perfect ratio of air and fuel for complete combustion. In gasoline engines, this ideal ratio is often around 14.7:1 (air to fuel). Running rich, as I was, actuallyreducespower, wastes fuel, and can lead to carbon buildup and other issues. I started to adjust my ECU and found that after reducing the fuel, I was gaining horsepower that I didn't know I had.

Stoichiometry is absolutely crucial for several reasons. First and foremost, it ensures complete combustion, maximizing the energy released from the fuel. This translates directly into more power and improved fuel efficiency. Secondly, a stoichiometric mixture minimizes harmful emissions. Catalytic converters, vital for reducing pollutants, are most effective when the exhaust gases are within a narrow range around the stoichiometric AFR. Finally, a balanced AFR protects your engine from damage. Running lean (too much air) can lead to excessive heat, detonation, and ultimately, engine failure. Running rich, besides wasting fuel and reducing power, can dilute the oil and cause premature wear.

What is Air-Fuel Ratio?

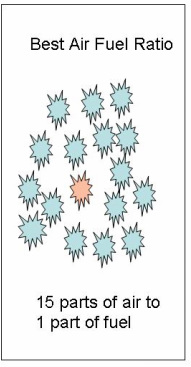

At its core, the air-fuel ratio (AFR) is simply the ratio of air to fuel in the mixture that your engine burns. It's a fundamental parameter that dictates how efficiently your engine operates. Imagine it as the recipe for an explosion – too much of one ingredient, and the whole thing falls apart. While 14.7:1 is often cited as the ideal, stoichiometric ratio for gasoline, the optimal AFR can vary depending on engine load, operating conditions, and the type of fuel used. For example, during acceleration, a slightly richer mixture (e.g., 13:1) might be preferred to provide extra power. Conversely, during cruising, a slightly leaner mixture (e.g., 15:1) can improve fuel economy.

Modern engines use sophisticated sensors and electronic control units (ECUs) to constantly monitor and adjust the AFR. Oxygen sensors in the exhaust stream provide feedback to the ECU, which then fine-tunes the fuel injectors to maintain the desired ratio. However, even with these advanced systems, things can go wrong. Leaks in the intake system, faulty sensors, or incorrect ECU programming can all throw off the AFR, leading to performance problems. Furthermore, after market components can often play a roll. Replacing your intake or exhaust system without a proper tune can also cause for less than optimal AFR.

Understanding the basics of AFR is essential for anyone who wants to get the most out of their engine. Whether you're a seasoned mechanic or just a curious car enthusiast, knowing how this ratio affects performance can help you diagnose problems, optimize your engine's tune, and ensure long-term reliability. By keeping a close eye on your AFR, you can unlock hidden power, improve fuel economy, and keep your engine running smoothly for years to come.

The History and Myths of Air-Fuel Ratio

The concept of controlling air-fuel mixtures is almost as old as the internal combustion engine itself. Early carburetors were crude devices, relying on basic principles of physics to meter fuel. However, they were notoriously imprecise, leading to inconsistent performance and high emissions. As engine technology advanced, so did the methods for controlling the AFR. Fuel injection systems, first introduced in the early 20th century, offered much greater precision and control compared to carburetors.

The advent of electronic fuel injection (EFI) in the 1970s marked a major turning point. EFI systems used sensors and computers to continuously monitor and adjust the AFR, leading to significant improvements in fuel efficiency, emissions, and performance. Today, modern engines utilize sophisticated EFI systems with multiple sensors, advanced algorithms, and closed-loop feedback control to maintain the optimal AFR under a wide range of operating conditions. Despite these technological advancements, several myths surrounding AFR persist. One common misconception is that "more fuel always equals more power." While it's true that a richer mixture can sometimes provide a slight power boost under specific conditions (e.g., during wide-open throttle), running excessively rich can actuallyreducepower and lead to other problems. Another myth is that a lean mixture is always better for fuel economy. While a slightly leaner mixture can improve fuel economy, running too lean can lead to overheating, detonation, and engine damage.

Another myth is the idea that aftermarket modifications will always increase horse power, and fuel economy. When adding these modifications without a proper tune, the AFR can become less than optimal. Understanding the history and debunking these myths is crucial for making informed decisions about engine tuning and maintenance. By separating fact from fiction, you can avoid costly mistakes and ensure that your engine is running at its best.

The Hidden Secrets of Air-Fuel Ratio

Beyond the basic principles of stoichiometry, there are several hidden secrets of the air-fuel ratio that can unlock even greater performance and efficiency. One key secret lies in understanding the dynamic nature of AFR. The optimal AFR is not a fixed value but rather a moving target that changes depending on various factors, including engine load, speed, temperature, and ambient conditions. Modern ECUs use complex algorithms to continuously adjust the AFR based on these parameters, but even the most sophisticated systems can benefit from fine-tuning.

Another secret is the importance of individual cylinder tuning. In some engines, the AFR can vary slightly between cylinders due to differences in intake manifold design or injector flow rates. By measuring the AFR in each cylinder individually, you can identify imbalances and make adjustments to optimize performance. This level of fine-tuning is often used in high-performance applications, such as racing engines. Furthermore, the type of fuel you use can significantly impact the optimal AFR. Different fuels, such as ethanol blends or racing fuels, have different stoichiometric ratios and require different tuning strategies. Using the wrong fuel or failing to adjust the AFR accordingly can lead to performance problems and even engine damage.

Finally, the condition of your engine components can also affect the AFR. Worn or damaged injectors, a dirty air filter, or a leaky exhaust system can all disrupt the AFR and lead to performance issues. Regularly inspecting and maintaining these components is essential for ensuring that your engine is running at its best. By uncovering these hidden secrets, you can take your understanding of AFR to the next level and unlock the full potential of your engine.

Recommendations for Optimizing Your Air-Fuel Ratio

Optimizing your air-fuel ratio (AFR) requires a multi-faceted approach that considers both the hardware and software aspects of your engine. A first recommendation is to invest in a reliable wideband oxygen sensor. This sensor provides accurate readings of the AFR in real-time, allowing you to monitor and adjust your engine's tune with precision. Unlike narrowband sensors, which only provide a limited range of data, wideband sensors can measure a much wider range of AFRs, making them essential for tuning and troubleshooting.

Another recommendation is to use a professional tuning software. Tuning software allows you to access and modify the parameters of your engine's ECU. With the correct tuning software, you can fine-tune the AFR, ignition timing, and other settings to optimize performance and efficiency. However, it's essential to have a solid understanding of engine tuning principles before attempting to modify your ECU. Incorrect tuning can lead to performance problems and even engine damage. Furthermore, make sure to conduct regular engine maintenance. A clean air filter, properly functioning injectors, and a leak-free exhaust system are essential for maintaining a stable and accurate AFR. Neglecting these maintenance tasks can lead to performance problems and even engine damage.

Finally, consider seeking professional help. If you're not comfortable tuning your engine yourself, it's best to consult with a qualified mechanic or tuner. A professional tuner can use specialized equipment and expertise to optimize your AFR and ensure that your engine is running at its best. By following these recommendations, you can unlock the full potential of your engine and enjoy improved performance, fuel efficiency, and reliability.

Understanding Lambda

Lambda is a term often used interchangeably with AFR, but it represents the ratio in a slightly different way. Instead of expressing the air-fuel ratio directly, lambda expresses it as a ratio relative to the stoichiometric AFR. A lambda value of 1.0 indicates a stoichiometric mixture, meaning the AFR is exactly at the ideal

14.7:1 (for gasoline). A lambda value greater than

1.0 indicates a lean mixture (more air than fuel), while a lambda value less than

1.0 indicates a rich mixture (more fuel than air).

Lambda is often preferred by engineers and tuners because it provides a normalized scale that is independent of the specific fuel being used. For example, the stoichiometric AFR for ethanol is different from that of gasoline, but a lambda value of 1.0 always represents the chemically correct mixture, regardless of the fuel. Understanding lambda is essential for interpreting AFR data and making informed tuning decisions. Most wideband oxygen sensors display AFR data in both AFR and lambda values, allowing you to easily monitor and adjust your engine's tune.

Lambda can also be used to calculate the excess air coefficient, which is a measure of the amount of air available for combustion relative to the stoichiometric amount. The excess air coefficient is directly proportional to lambda. Lambda = Actual AFR / Stoichiometric AFR. The target lambda will vary depending on the requirements of an engine, for example, engines that are used in track racing may target 0.85 -

0.90 to maximize power. Where are engines that are used for economy purposes may be

1.1 -1.15. This is something that will be different depending on the purpose of the engine.

Tips for Fine-Tuning Your Air-Fuel Ratio

Fine-tuning your air-fuel ratio (AFR) is an art and a science that requires patience, attention to detail, and a solid understanding of engine dynamics. One important tip is to start with a conservative approach. When making changes to your ECU, it's always best to start with small adjustments and gradually work your way towards the optimal AFR. Making large, sudden changes can lead to performance problems and even engine damage.

Another tip is to pay attention to your engine's behavior. Monitor your engine's performance closely and listen for any signs of trouble. Detonation, misfires, and excessive exhaust smoke are all indicators that your AFR is not correct. It's important to address these issues promptly to prevent further damage. Additionally, consider using data logging. Data logging allows you to record various engine parameters, including AFR, engine speed, throttle position, and ignition timing. By analyzing this data, you can identify trends and make informed tuning decisions.

Furthermore, make sure to tune under realistic conditions. The optimal AFR can vary depending on engine load and speed, so it's important to tune your engine under a variety of driving conditions. Avoid tuning your engine solely on a dynamometer, as this may not accurately reflect real-world driving conditions. Remember to verify what fuel grade your ECU is tuned for and only use that fuel grade. This is extremely important because a low-grade fuel will ignite quicker, which can lead to engine knocking, which can cause damage to the internals of your engine. By following these tips, you can fine-tune your AFR with confidence and achieve optimal performance and efficiency.

Understanding Open Loop vs. Closed Loop

Modern engine management systems operate in two primary modes: open loop and closed loop. Understanding the difference between these modes is crucial for effectively tuning your AFR. In closed-loop mode, the ECU uses feedback from oxygen sensors to continuously adjust the AFR. The oxygen sensors measure the amount of oxygen in the exhaust gas and send this information back to the ECU, which then adjusts the fuel injectors to maintain the desired AFR.

In open-loop mode, the ECU ignores the feedback from the oxygen sensors and relies on pre-programmed maps to determine the AFR. Open-loop mode is typically used during cold starts, wide-open throttle, and other situations where the ECU needs to prioritize performance over emissions. When tuning your AFR, it's important to understand which mode your engine is operating in. In closed-loop mode, the ECU will attempt to correct any deviations from the target AFR, so it's important to make sure that your target AFR is accurate. In open-loop mode, the ECU will rely solely on your pre-programmed maps, so it's even more important to make sure that these maps are accurate.

Many tuning software programs allow you to adjust the AFR in both open-loop and closed-loop modes, giving you precise control over your engine's performance. Often engines can automatically switch between the two modes. In closed loop, an ECU is monitoring the AFR through the use of oxygen sensors and adjusting the fueling based on the readings of these sensors. Open loop relies on predetermined values that is programed within the ECU's program. By understanding the concept of Open and Closed loop, you can effectively dial in what you need for your AFR.

Fun Facts About Air-Fuel Ratio

Did you know that the optimal air-fuel ratio for gasoline was discovered by accident? In the early days of engine development, engineers experimented with different fuel mixtures, often without a clear understanding of the underlying principles. It was through trial and error that they eventually discovered the stoichiometric ratio of approximately 14.7:1, which provides the best balance of power, efficiency, and emissions. Another fun fact is that the air-fuel ratio can be affected by altitude. As you climb higher in altitude, the air becomes thinner, which means there is less oxygen available for combustion. This can cause the AFR to become richer, leading to reduced performance and increased emissions. Modern ECUs compensate for altitude changes by adjusting the fuel injectors to maintain the desired AFR.

Also, different fuels have different stoichiometric ratios. For example, ethanol has a stoichiometric ratio of approximately 9:1, while methanol has a stoichiometric ratio of approximately 6.5:1. This means that engines running on these fuels require different tuning strategies than engines running on gasoline. Another little known fact is that extreme temperatures can effect AFR, often requiring adjustment of the mixture. The ECU will try to adjust the AFR, but it might be beneficial to tune your own AFR for the ideal conditions.

Finally, the air-fuel ratio is not the only factor that affects engine performance. Other factors, such as ignition timing, compression ratio, and valve timing, also play a significant role. Optimizing all of these factors in conjunction with the AFR is essential for achieving peak performance. These fun facts highlight the complexity and fascinating history of the air-fuel ratio, a fundamental parameter that continues to shape the design and operation of internal combustion engines.

How to Measure Your Air-Fuel Ratio

Measuring your air-fuel ratio (AFR) accurately is essential for tuning and troubleshooting your engine. The most common method for measuring AFR is to use a wideband oxygen sensor. These sensors are typically installed in the exhaust system and provide real-time readings of the AFR. Wideband oxygen sensors are much more accurate and responsive than narrowband sensors, making them essential for tuning and diagnosing engine problems. To measure the AFR, you'll need a wideband oxygen sensor, a data logger, and a laptop or other device for displaying the data.

Install the wideband oxygen sensor in the exhaust system, typically in the downpipe or collector. Connect the sensor to the data logger, which will record the AFR data. Connect the data logger to your laptop and use tuning software to display the data in real-time. Start your engine and allow it to warm up to operating temperature. Monitor the AFR data as you drive or run your engine on a dynamometer. Pay attention to the AFR under different engine loads and speeds. Look for any deviations from the target AFR and make adjustments to your ECU as needed.

Another method for measuring AFR is to use an exhaust gas analyzer. These devices are typically used in professional tuning shops and provide a more detailed analysis of the exhaust gases. Exhaust gas analyzers can measure not only the AFR but also the levels of various pollutants, such as hydrocarbons, carbon monoxide, and nitrogen oxides. The location of the wideband oxygen sensor is extremely important. Make sure to follow the manufactures recommended location for the best reading. By following these steps, you can accurately measure your AFR and make informed decisions about your engine's tune.

What If Your Air-Fuel Ratio Is Off?

An incorrect air-fuel ratio (AFR) can lead to a variety of problems, ranging from reduced performance and poor fuel economy to engine damage. If your AFR is too lean (too much air), your engine may experience detonation, misfires, and overheating. Detonation, also known as "knocking" or "pinging," occurs when the air-fuel mixture ignites spontaneously before the spark plug fires. This can damage the pistons, cylinder heads, and other engine components. Misfires occur when the air-fuel mixture fails to ignite properly. This can lead to reduced power, poor fuel economy, and rough idling.

Overheating can occur when the engine is running too lean, as there is not enough fuel to cool the combustion chamber. This can lead to engine damage, such as warped cylinder heads and cracked blocks. If your AFR is too rich (too much fuel), your engine may experience reduced power, poor fuel economy, and excessive exhaust smoke. A rich AFR can also lead to carbon buildup on the spark plugs and valves, which can reduce engine performance. Furthermore, a rich AFR can dilute the engine oil, leading to premature wear of engine components.

In addition to these performance and reliability issues, an incorrect AFR can also lead to increased emissions. A lean AFR can increase emissions of nitrogen oxides (NOx), while a rich AFR can increase emissions of hydrocarbons (HC) and carbon monoxide (CO). If you suspect that your AFR is off, it's important to diagnose the problem and take corrective action. The first step is to check for any obvious problems, such as a dirty air filter, a faulty oxygen sensor, or a leaky exhaust system. If you can't find any obvious problems, you may need to consult with a qualified mechanic or tuner. Correct AFR is extremely important and is why manufacturers go to great lengths to keep this consistent.

Listicle: 5 Signs Your Air-Fuel Ratio Needs Attention

Here's a listicle outlining five key signs that your air-fuel ratio (AFR) might be out of whack and needs some attention:

- Poor Fuel Economy: A sudden or gradual decrease in your vehicle's fuel economy is a telltale sign of an imbalanced AFR. A rich mixture wastes fuel, while a lean mixture can reduce power and efficiency, both leading to more frequent trips to the gas station.

- Rough Idling: An erratic or unstable idle, characterized by the engine sputtering, shaking, or stalling, can indicate an improper AFR. A lean mixture can cause misfires at idle, while a rich mixture can foul the spark plugs.

- Reduced Power: If your vehicle feels sluggish or unresponsive, especially during acceleration, it could be due to an incorrect AFR. A lean mixture can limit power output, while a rich mixture can bog down the engine.

- Excessive Exhaust Smoke: Unusual exhaust smoke can signal an AFR problem. Black smoke typically indicates a rich mixture, with unburned fuel being expelled from the engine. Blue smoke can indicate that engine oil is also being burned.

- Check Engine Light: The infamous "Check Engine Light" is often triggered by AFR-related issues. The ECU monitors various engine parameters, and if it detects a deviation from the target AFR, it will illuminate the warning light.

If you notice any of these signs, it's important to investigate the cause and take corrective action. Ignoring these symptoms can lead to more serious engine problems down the road. Start by checking the basics, such as the air filter, spark plugs, and oxygen sensors. If the problem persists, consult with a qualified mechanic or tuner to diagnose and resolve the issue.

Question and Answer Section

Here are some frequently asked questions about air-fuel ratio (AFR):

Q: What is the ideal AFR for gasoline engines?

A: The ideal, stoichiometric AFR for gasoline engines is often cited as 14.7:1 (air to fuel). However, the optimal AFR can vary depending on engine load, operating conditions, and the type of fuel used.

Q: What happens if my AFR is too lean?

A: A lean AFR (too much air) can lead to detonation, misfires, overheating, and engine damage.

Q: What happens if my AFR is too rich?

A: A rich AFR (too much fuel) can lead to reduced power, poor fuel economy, excessive exhaust smoke, and carbon buildup.

Q: How can I measure my AFR?

A: The most common method for measuring AFR is to use a wideband oxygen sensor installed in the exhaust system.

Conclusion of Air-Fuel Ratio – Why Getting It Right Is Critical for Performance

In conclusion, the air-fuel ratio is a crucial parameter that directly impacts engine performance, fuel efficiency, emissions, and long-term reliability. By understanding the principles of stoichiometry, monitoring your AFR, and making informed tuning decisions, you can unlock the full potential of your engine and ensure that it's running at its best. Whether you're a seasoned mechanic or just a curious car enthusiast, mastering the art and science of AFR is essential for maximizing your engine's performance and longevity.

Post a Comment for "Air-Fuel Ratio – Why Getting It Right Is Critical for Performance"